-

The Fuel Oil Additive for VLSFO/HFO

BFT-C

Bunker Fuel Treatment“BFT-C" has developed for the soot & black smoke reduction and has dramatical effect of Sludge Dispersant.

What is BFT-C? Bunker fuel treatment?

It is a cleaning effect additive to prevent potential troubles by sludges during VLSFO/HFO use.

It will demonstrate dramatical effect of sludge reduction and sludge clean out in the Fuel Tank, Fuel Nozzles, Cylinders etc.

BFT moderates the occurrence of soot & black smoke by fuel reformulation and will prove an exhaust improvement in environmental loads.

We have been receiving great feedback from our customers about its excellent sludge dispersant effect.

Major Attributes:

-

Sludge Dispersion & ReductionCleans FO Fuel Tank and Fuel system

-

Flash Point at 62 Degree CBFT-C can be stored in the Engine Room

According to "2014 SOLAS II" - The Flash Point under 60 Degree C is not allowed to store in the Engine Room.

-

Combustion AccelerationMinimization of The Soot & Black Smoke Exhaust.

Add "BFT-C", an additive for VLSFO/HFO, to prevent sludge formation in the Tanks and the Fuel System.

"BFT-C" dramatically disperse the Sludge composed of asphaltene in VLSFO/HFO and prevent from re-formation.

It also keeps Tanks and the Fuel System clean.

- A Countermeasure for Sudden Trouble by Sludge due to mixing of different VLSFOs.

- Continuously Disperse and Clean out the Sludge by "BFT-C" on the Scrubber Installed Vessels for SOx Regulation

Sludge Volume Observation

(Monitored at the Vessel)

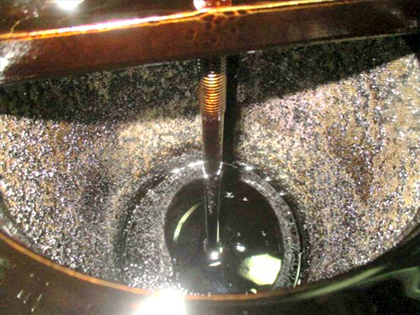

1. The Strainer Aspect Comparison between "Before BFT Use" and "After BFT USE".

* Added "BFT" only one time with mixing ratio at 1/5,000 after fuel filled. The Vessel has never used the FO Tank Cleaning Additives. (The vessel was 18 Years Old)

-

- Before "BFT" use.

-

- After "BFT" use.

Observation :

Confirmed an excellent cleaned conditions at surface of the metal filter where Asphaltenes were dispersed and removed from the system.

2. Observation for an inside condition of FO Tank after "BFT" use.

* Added "BFT" only one time with mixing ratio at 1/7,000 after fuel filled. The Vessel has never used the FO Tank Cleaning Additives. (The vessel was 10 Years Old)

-

- Side-wall

-

- Bottom

Observation :

Confirmed an excellent cleaned conditions in an inside of the FO tank even though adding "BFT" after fuel filled.

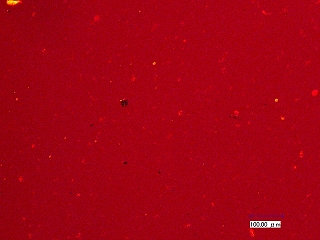

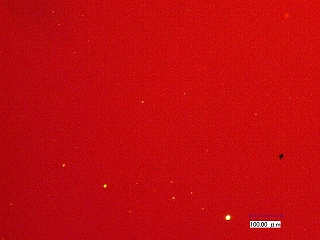

Sludge Volume Observation

(Monitored via the Laboratory Test)

Observed the sludge condition via Microscope.

* Sludges were observed as white and black spots.

-

- Only FO(a lens with a magnifying power of 300)

-

- FO plus "BFT" with a mixing ratio of 1/10,000(a lens with a magnifying power of 300)

Measurement in May 2016

Directions

Add "BFT" directly into fuel holding tank at range of 1/5,000 to 1/10,000 mixing ratio each time tanks are filled.

(The mixing ratio should be considered by taking an operation conditions)

If you need to take immediate action with your sludge issues, BFT is your countermeasure to prevent potential engine and fuel system failures.

Please take a look at this product for your help.

-

The fuel oil (MGO/LSFO) additives

MGI

Marine Gasoil ImproverMGI is a lubricity improver which will help reduce potential damage from the low quality of MGO/LSFO due to SOx regulations.